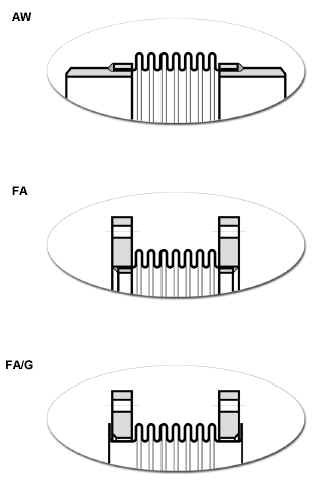

Terminals

We can produce expansion joints

complete of flanges and to be pipe ends. The different terminal

are generally produced in carbon steel. On request, it is possible

to use stainless steel. Standard flanges are bored according to

UNI - ANSI rules, or special and in above mentioned materials.

|

|

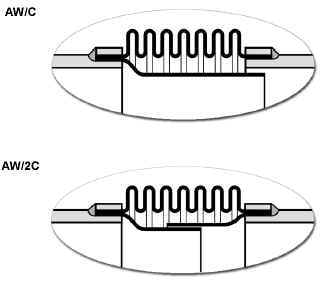

Sleeve

To avoid direct contact between

bellow and fluid a sleeve is welded on the internal side of the

expansion joint. It allows to reduce thermal strains, to reduce

loss of head, turbulences and erosion.

|

|

External protection

To protect waves from foreign

bodies or to facilitate the application of the insulation, bellow,

can externally be wound by a plate, generally in carbon steel.

|

|

|

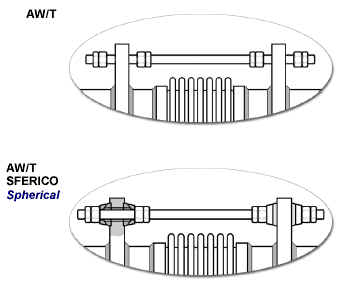

Tie rods

According to the use we can

distinguish:

-

tie rods as run limiting device

-

tie rods for pre-setting to the

mounting

-

tie rods to support the thrust

due to internal pressure.

|

|

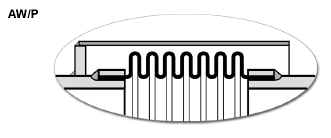

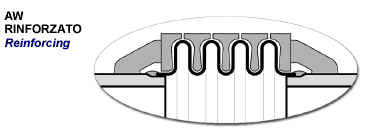

Reinforcing rings

When we have to plan a bellow

subjected to high pressure it is necessary to use reinforcing

rings made of carbon steel sheet. Besides uniformly distributing

the compensator, they also act like run limiting devices.

|

|

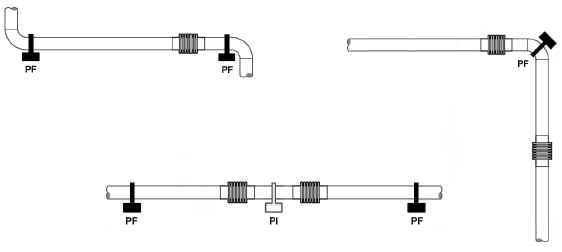

Fixed points

To allow to the axial expansion

joint to perfectly carry out its function, it is necessary to

limit strengths (displacements and rotations) generated on

pipeline, using fixed points.

Usually fixed points are distinguished in:

|

|

|

Guides

An appropriate positioning of fixed

points and guides in a pipeline, can check the movement of the

expansion joint.

|

|